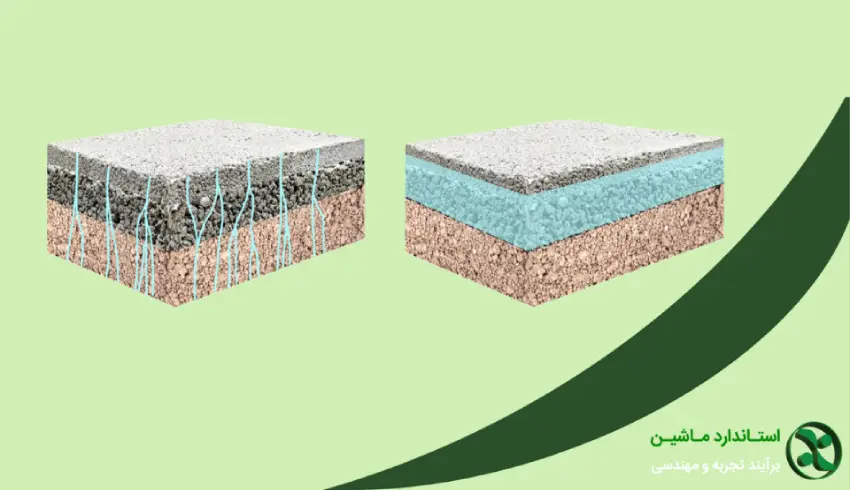

In recent decades, with the rapid growth of urbanization and the expansion of impervious surfaces in urban areas, issues such as sudden floods, depletion of groundwater resources, and increased surface temperatures have gained increasing attention. In response to these challenges, porous concrete (Permeable Concrete) has emerged as an innovative and sustainable solution in civil engineering. Porous concrete is a type of concrete with a special structure that, due to significant porosity, allows water penetration and air passage.

Unlike conventional concretes designed for increased compressive strength, this type of concrete is made to improve urban runoff management, reduce heat island effects, and increase water infiltration into subsurface layers. In this article from Standard Machine, we first examine the structure and composition of porous concrete, then compare its advantages and disadvantages with traditional concrete, and finally analyze the applications and implementation methods of these novel materials in civil projects.

What is porous concrete?

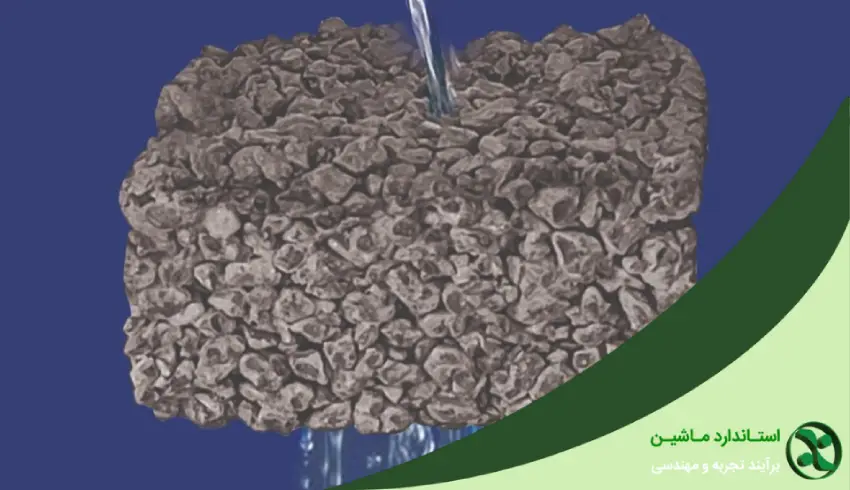

Porous concrete, or sponge concrete, is a special type of concrete that, unlike ordinary concrete, has high porosity and allows water and air to pass through. This concrete has a coarse aggregate structure without sand, meaning the voids between the aggregates remain and these spaces create pathways for water and air.

The structure of this concrete is similar to a stone sponge. There are many voids between the aggregates through which water easily passes. Porous concrete is typically made from the following components:

-

Portland cement

-

Coarse aggregate (such as crushed gravel)

-

Low amount of water

-

Little or no sand or fine aggregates

Foam (air bubbles) may be added to the mix of cement, water, and sometimes sand, which creates air pockets within the concrete, reducing density and increasing porosity.

Air content in porous concrete

In porous concrete, typically 15 to 30 percent of the total volume is void or air. These voids form between the coarse aggregates because, unlike regular concrete, porous concrete contains little to no fine aggregates.

What problem does porous concrete solve?

In modern cities, most surfaces such as streets, sidewalks, and parking lots are impervious, meaning water cannot be absorbed into the ground when it rains, resulting in:

-

Urban flooding

-

Runoff carrying pollutants to rivers

-

Reduced recharge of groundwater aquifers

Porous concrete is designed to solve this problem by allowing water to pass through and directly infiltrate the soil beneath.

Characteristics of sponge concrete

With the growing need for lightweight, economical, and environmentally friendly materials, understanding the technical and performance characteristics of sponge concrete has gained special importance. In this section, we explain the most important properties of this building material:

-

Lightweight: Due to air bubbles in its structure, sponge concrete has a much lower density than regular concrete, usually between 300 to 1800 kg/m³.

-

Good thermal and acoustic insulation: Due to its porous structure and entrapped air, it provides high thermal and sound resistance, effectively optimizing energy consumption.

-

Adjustable compressive strength: The compressive strength can be adjusted based on density and mix ratios, usually ranging between 1 to 15 MPa.

-

Easy and rapid production: Using foam generators, this concrete can be produced quickly and easily without the need for vibration or compaction.

-

Self-leveling property: Sponge concrete naturally has high flowability and self-levels, making it easy to place in molds or on surfaces.

-

Environmental compatibility: Due to the use of recyclable raw materials and less resource consumption, sponge concrete is considered eco-friendly.

-

Not suitable for heavy loads: Mainly used in non-structural applications and not recommended for heavily loaded structural parts unless specially formulated.

Types of porous or sponge concrete

Porous concretes are primarily designed to allow water infiltration and include:

-

No-fines Concrete: Contains only coarse aggregate, cement, and water. High porosity, suitable for surface drainage and rainwater passage.

-

Gap-graded Concrete: Contains a small amount of fine aggregates. Has higher compressive strength than no-fines but lower permeability.

-

Polymer Pervious Concrete: Made using polymer resins instead of cement. Has higher resistance to chemicals and environmental factors.

-

Fiber-reinforced Pervious Concrete: Includes steel, polymer, or glass fibers to improve tensile strength and control cracking.

Production of porous concrete

The production process involves eliminating fine aggregates (sand) to create a highly porous structure, mainly used for water passage and drainage. The production steps are as follows:

Execution method of porous concrete

-

Preparation of materials: Selection and preparation of raw materials start the process. Main materials include Portland cement type I or II, coarse aggregates sized around 10 to 20 mm, and specific amounts of water. Unlike regular concrete, no or minimal sand is used to create permeability.

-

Mix proportion determination: Typical cement to coarse aggregate ratios range from 1:4 to 1:6, and water-to-cement ratio (W/C) between 0.27 to 0.35. These must be carefully selected as excessive water can reduce porosity, while insufficient water decreases workability and strength.

-

Mixing materials: Coarse aggregates are placed in the mixer first, then cement is added to form a dry mix. Water is gradually added while mixing until uniform coating of particles is achieved.

-

Placing concrete in molds: The mix must be immediately poured. Vibration is avoided to prevent void filling and loss of permeability; light rolling or manual tamping is used instead.

-

Curing: The concrete surface is covered with plastic sheets or kept moist, usually for seven days, adjustable by environmental conditions.

-

Testing and quality control: Porosity, compressive strength, and permeability are tested to ensure performance. Drainage capacity is checked to evaluate runoff reduction and groundwater recharge efficacy.

Advantages of sponge concrete

The advantages that make porous concrete popular in civil, construction, and infrastructure projects include:

-

Very lightweight

-

Good thermal and acoustic insulation

-

High workability and formability

-

Prevents energy loss

-

Fire resistance

-

Environmentally friendly

-

Reduces execution costs

-

Reduces load on structure and foundation

-

Suitable coverage and filling ability

-

-

Water-to-cement ratio (W/C): Needs precise control; too much water fills voids reducing permeability, too little reduces workability.

-

Aggregate size and grading: Usually uniform coarse aggregates (10-20 mm) with minimal fines; proper grading is key to creating voids for water infiltration.

-

Cement type and amount: Affects properties and durability; use quality cement and optimal amounts.

Additives in porous concrete

Although the basic components are simple (coarse aggregate, cement, and water), additives can greatly improve quality, durability, workability, and performance. Key additives include:

-

Plasticizers: Improve flow without extra water, better cement distribution

-

Air-entrainers: Create fine air bubbles for freeze-thaw durability

-

Fibers: Reinforce tensile strength and control cracks (steel, polymer, glass fibers)

-

Mineral additives: Such as microsilica and fly ash to improve durability and reduce permeability

-

Accelerators and retarders: Adjust setting times for different climates

-

Anti-freeze agents: Prevent freezing in cold weather

Air-entraining agents in concrete production

Air-entraining agents are important additives, especially in cold climates, to increase freeze-thaw durability. They create uniform small air bubbles, improving workability without increasing water. This also benefits concrete transport and pumping.

Problems of porous concrete

Despite many benefits, porous concrete has limitations that must be considered in application and maintenance. Its compressive strength is lower than regular concrete, so it is not recommended for heavy traffic or load-bearing areas unless specially formulated. Also, pores may clog over time with dust, soil, or sludge, reducing permeability; periodic cleaning and maintenance are necessary. Its production requires skill because vibration is prohibited and W/C ratio must be precisely controlled, or performance will suffer. Chemical environments with chlorides or acids may reduce durability without protective measures.

Factors affecting porous concrete production

Several factors influence quality, performance, durability, and permeability. Understanding these is essential for producing optimal porous concrete.

-

-

Conclusion:

Pervious concrete is a modern and intelligent material in the field of sustainable urban development. When properly designed and implemented, it can contribute significantly to solving various environmental and urban challenges.