Pneumatic screw pumps are the most common feeders for pneumatic conveying of dry and free-flowing powdery materials such as cement, raw meal, lime, gypsum, fly ash, granulated blast furnace slag, coal dust, filter dust, alumina, and various other minerals. These pumps are mainly used for conveying materials from mills and filters to silos, from silo to silo, from silos to packing stations, or for loading and unloading ships, trucks, and railcars. Pneumatic screw pumps are high-performance units available in various sizes with material conveying capacities from 5 to 450 m³/h, suitable for all dry, loose, and powdered materials, and for conveying distances from 25 to 500 meters.

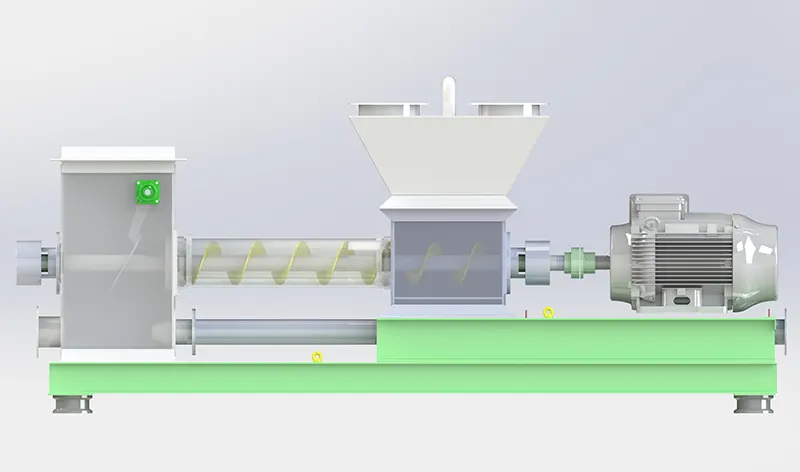

Key Components:

- Material Inlet: Top-mounted pump hopper with integrated dedusting system

- Conveying Mechanism: High-speed rotating screw for material feed

- Outlet Section: Equipped with a non-return valve for material discharge

- Double-Ended Bearing System

- Material/Gas Mixing Chamber

- Conveying Gas and Line Connections

- Accelerating Nozzle

- Pressure Condition: P1 ≈ P2 + 0.3 bar

The material is fed into the screw pump by gravity. The core element is the high-speed rotating screw that continuously feeds material from the hopper to the transport line. The material flow is not directly created by the screw, but rather in a chamber located between the end of the screw and the non-return valve, which fills with compressed material during operation. The material drops into the discharge box, where it is carried by conveying air generated by a compressor, through nozzles, and then into the silo.

Technical Specifications – Pneumatic Screw Pump (Standard Machine Co.):

| Parameter | Value |

| Transport Material | Cement |

| Lifting Height | Up to 35 m |

| Compressed Air Consumption | 11–12 m³/min |

| Working Pressure (Air) | 1.2 bar |

| Motor Power | 37 kW |

| Overall Dimensions (L×W×H) | 3460×1620×520 mm |

| Weight | 1100 kg |

| Transport Pipeline Diameter | 5 inch |

| Capacity | Up to 100 t/h |