فونداسیون

جهت استقرار قسمت های مختلف سیستم بچینگ، نیاز به فونداسیون و زیر سازی مناسب می باشد. لذا پس از تسطیح و کوبیدن منطقه مورد نظر با توجه به ابعاد سازه ها، اقدام به ساخت فنداسیون بتنی در محل می گردد. البته در برخی موارد با توجه به نیاز پروژه از سازه فلزی و یا بچینگ پلانت موبایل استفاده می شود که نیازی به فونداسیون بتنی ندارد.

اتاق فرمان

اتاق فرمان مرکز کنترل و هدایت کلیه عملیات بچینگ پلانت جهت ساختن بتن است و تابلوی فرمان و سیستم های الکتریکی هدایت دستگاه در آن مستقر می باشد.

سیستم اتوماسیون، مانیتورینگ و ثبت اطلاعات استفاده شده در بچینگ های استاندارد ماشین که تماماً با بهره گیری از دانش فنی و توان اجرایی مجموعه طراحی و ارائه شده است، با دقت بسیار بالا بر اساس پارامترهای تعیین شده توسط آزمایشگاه عمل میکند و پس از دریافت فرمان اجرا، اپراتور نقشی در فرایند بارگیری ندارد. لذا عملیات مذکور با دقت و هماهنگی مطلوب انجام می پذیرد.

علاوه بر کنترل اتوماتیک ، اپراتور می تواند توسط پنل دستی موجود در کابین کلیه عملیات را بصورت دستی و نیمه اتوماتیک نیز انجام دهد.

استفاده از صفحه نمایش با ابعاد بزرگ در سیستم کنترل بچینگ پلانت موجب میشود تا وضعیت دریچه ها و توزین مصالح، مواد و افزودنی ها به صورت واضح به نمایش درآید و این امکان براي اپراتور فراهم است تا در کنترل بچینگ پلانت قدرت بیشتری داشته باشد. نمایشگر دیجیتال و سیستم کنترل کاملاً اتوماتیک PLC زیمنس و تابلوهای برق با لوازم کره جنوبی همراه با سیستم نرم افزاری اختصاصی و انحصاری استاندارد ماشین با قابلیت کارکرد تمام اتومات ، بروز رسانی و عیب یابی با قابلیت کنترل از راه دور.

مانیتورینگ با استفاده از LED 22، و مانیتورینگ توسط نرم افزار winCC Siemens

ثبت اطلاعات در سیستم کنترل به صورتی است که در هر زمان، آزمایشگاه یا دیگر بخش هاي مسئول به تمامی پارامترها از جمله وزن و زمان،دسترسی خواهند داشت. این اطلاعات بر اساس فایل های استاندارد آفیس تحت ویندوز به راحتی قابل خواندن و ویرایش هستند. همچنین قابلیت گزارش گیری بر اساس عملکرد بچینگ ، راننده ،هر بچ میکسر بصورت مجزا و… امکان پذیر است.

در اتاق فرمان موارد ایمنی ریز می بایست رعایت گردد:

– در اتاق فرمان می بایست فضای کافی جهت حرکت اپراتور به آسانی وجود داشته باشد.

– تابلوی فرمان باید طوری جانمایی گردد تا احتمال برخورد سهوی اپراتور با آن وجود نداشته باشد.

– کلیدهای تابلو فرمان دارای حفاظ مناسب باشد.

– حتما کلید قطع برق اضطراری (Emergency) در تابلو فرمان تعبیه شده باشد.

– در سیستم برق تابلو از رله و فیوزهای مناسب استفاده شده باشد.

– در اتاق فرمان جهت کار در شب روشنایی مناسب وجود داشته باشد.

– در تابلو فرمان به جای استفاده از کلیدهای برجسته، از کلیدهای رینگ دار استفاده گردد تا در اثر برخورد سهوی عمل نکند.

– اتاق فرمان می بایست به گونه ای طراحی شده باشد تا اپراتور نسبت به سایر همکاران خود در سکوی بچینگ دید کافی داشته باشد.

– استقرار یک عدد کپسول اطفاء حریق جعبه کمک های اولیه و چراغ قوه در اتاق فرمان ضروری است.

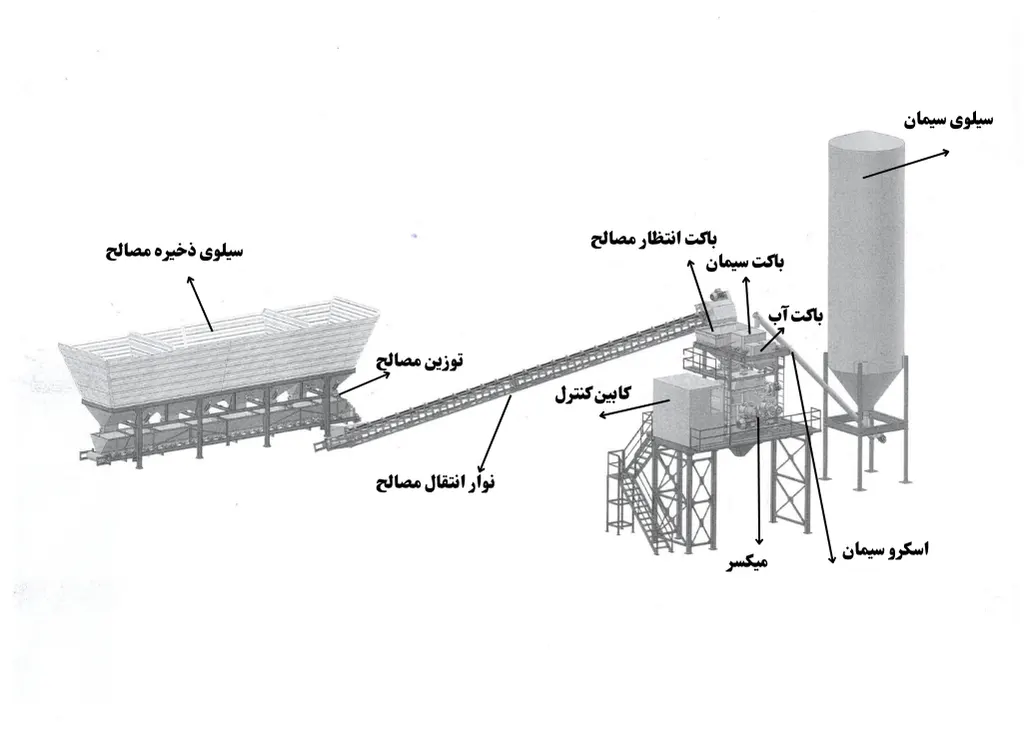

میکسر یا دیگ مخلوط کننده مصالح (Mixer)

دیگ مخلوط کننده یا میکسر مصالح بر روی سکوی بچینگ واقع شده است و عملیات ساخت بتن در میکسر بتن صورت می گیرد. کلیه مواد اولیه پس از تخلیه توسط واگن بالابر در میکسر مخلوط و بتن آماده شده جهت بارگیری در تراک میکسر از دریچه خروجی خارج می گردد.

اسکرو (Screw)

اسکرو لوله ای است که در آن مارپیچی هدایت کننده قرار دارد و جهت انتقال سیمان از داخل سیلوها به میکسر مواد مصالح در بچینگ از آن استفاده می شود.

سیستم بالابر و واگن حمل مصالح

جهت حمل و انتقال مصالح سنگی از دریچه های پنوماتیک قسمت بالای دپوی مصالح به میکسر از واگن مخصوصی که بر روی ریل بالابر مستقر می باشد استفاده می شود.

سیلوهای سیمان

سیلوها محل نگهداری و دپوی سیمان بوده و با توجه به ظرفیتشان دارای اندازه های مختلفی می باشند. مجموعه استاندارد ماشین تولیدکننده سیلوی سیمان نیست اما با بهترین تولیدکنندگان کشور همکاری دارد و در صورت نیاز مشتریان شما می توانید از خدمات این مجموعه ها استفاده کنید.

دپوی مصالح سنگی

مصالح سنگی مورد نیاز جهت ساخت بتن شامل ماسه شسته، شن نخودی و شن بادامی می باشد که در منطقه همجوار ماشین بچینگ با ساخت دیواره های حائل از یکدیگر مجزا می گردند.

بسیاری از فعالان صنعت ساختمان به دنبال خرید بچینگ پلانت هستند. قبل از خرید، به ابعاد و ظرفیت تولید دستگاه توجه کنید. معمولاً دستگاههای کوچکتر قدرت و کارایی کمتری دارند. بنابراین بر اساس نیاز خود، ابعاد مناسب را انتخاب کنید و اطمینان حاصل کنید که استفاده از دستگاه آسان باشد. شرکت استاندارد ماشین تولید کننده برتر بچینگ پلانت های ثابت و متحرک در ظرفیت های تولیدی مختلف در کشور است.

خرید بچینگ پلانت از شرکت استاندارد ماشین میتواند تجربهای ساده و کارآمد باشد. ابتدا، مشتریان میتوانند با مراجعه به وبسایت رسمی شرکت، اطلاعات جامع و دقیقی درباره محصولات مختلف و ویژگیهای بچینگ پلانت را کسب کنند و پس از بررسی ، مشاوران مجرب شرکت آمادهاند تا به سوالات مشتریان پاسخ دهند و راهنماییهای لازم را ارائه کنند.

در مرحله بعد، مشتریان میتوانند با انتخاب مدل مورد نظر، مراحل خرید را آغاز کنند. پس از نهایی شدن خرید، تیم فنی شرکت پس از اعلام آماده بودن پیش نیاز های نصب توسط خریدار محترم، اکیپ نصب و راه اندازی ما بصورت رایگان اعزام می گردد و خدمات پس از فروش را نیز به مشتریان ارائه میدهد تا از عملکرد بهینه و رضایت کامل آنها اطمینان حاصل گردد.

بعد از نصب و راه اندازی، تیم ما به اپراتور آموزش های لازم را می دهد که معمولا نیازمند دو روز زمان می باشد و پس از آن صلاحیت اپراتور را جهت بهره برداری از دستگاه تایید می نمایند. محصولات استاندارد ماشین دارای 12 ماه گارانتی و 10 سال خدمات پس از فروش می باشد و علاوه بر آموزش کامل نکات به اپراتور، دفترچه های تعمیر و نگهداری را خدمت خریدار محترم تقدیم می نماییم. جهت استعلام قیمت و خرید بچینگ پلانت، به وبسایت استاندارد ماشین مراجعه کنید و یا میتوانید با مشاوران ما تماس بگیرید تا راهنمایی لازم را دریافت کنید.

قیمت بچینگ

بچینگ بتن در کارگاههای صنعتی برای تولید فرآورده هایی مانند بتن معمولی که مناسب اکثر پروژههای عمرانی هستند، بتن روسازی برای روسازی خیابانها، بزرگراهها، بتن حجیم یا RCC، بتن لولههای بتنی و بتن مورد نیاز بلوک سازی به کار میرود و به مشتریان عرضه میشود. در نظر داشته باشید که هزینه راهاندازی یک ایستگاه تولید بتن معمولاً کمتر از خرید بتن آماده است و به همین دلیل، پیمانکاران پروژههای بزرگ مانند سدسازی، پلسازی و برجسازی تمایل دارند ایستگاههای تولید بتن را متناسب با نیاز پروژه در محل کار خود ایجاد کنند.

شرکت استاندارد ماشین یکی از بهترین ارائه دهندگان انواع پمپ بتن، بچینگ پلانت سیار و ثابت در ظرفیت های تولیدی مختلف در کشور است که به دلیل ارائه محصولاتی با کیفیت و کاربردی، محبوبیت زیادی کسب کرده است و علاوه بر کیفیت، قیمت مناسب این دستگاهها نیز از دلایل موفقیت این شرکت است. شما میتوانید بچینگ بتن را با قیمت مناسب از شرکت استاندارد ماشین خریداری کنید. برای اطلاع از قیمت های این دستگاهها، با شمارههای موجود در وبسایت شرکت تماس بگیرید.

قیمت بچینگ نو

قیمت خرید دستگاه بچینگ نو به مدل دستگاه، ظرفیت محصول دهی، توان مصرفی و برند آن مرتبط است. اگر دستگاه از قدرت و کیفیت بالایی برخوردار باشد، به طور طبیعی هزینه بیشتری را می بایست پرداخت کنید. همچنین، دستگاههایی که در تولید بتن سرعت بیشتری دارند، معمولاً قیمت بالاتری دارند. با توجه به نوسانات شدید بازار از جمله قیمت ارز امکان ارائه قیمت دقیق در سایت نیست و اگر شما هم می خواهید از لیست قیمت بچینگ نو و مدل های ارائه شده در بازار در سال 1403 مطلع شوید می توانید با شرکت استاندارد ماشین تماس حاصل فرمایید.

فروش بچینگ پلانت در ایران

بچینگ پلانت (Batching Plant) یکی از تجهیزات مهم در صنعت بتنسازی است که برای تولید بتن با کیفیت بالا و به صورت انبوه استفاده میشود. با توجه به توسعه زیرساختها و پروژههای مسکن، تقاضا برای ساخت بتن باکیفیت در ایران افزایش یافته که منجر به رشد بازار بچینگ پلانت و فروش بچینگ شده است و بنابراین شرکت های مختلف تولیدکننده بچینگ پلانت در ایران، مدلها و ظرفیتهای مختلفی از این تجهیزات را عرضه میکنند. خریداران نیز به دنبال بچینگ پلانت هایی هستند که دارای کیفیت بالا و مطابق با استانداردهای ملی و بینالمللی باشند. اما این نکته حائز اهمیت است که ارائه خدمات پس از فروش و تعمیر از عوامل مهم در انتخاب و خرید بچینگ پلانتها است تا مشتریان بتوانند در طول دوره استفاده از تجهیزات، پشتیبانی لازم را کسب نمایند.

استاندارد ماشین شرکتی مرجع در صنعت تولید تجهیزات و ماشین آلات ساختمانی و بتنی است و در طول بیش از سه دهه فعالیت خود، اعتماد بسیاری از شرکت ها و کارخانجات تولیدی در صنایع بتن را جلب نموده و پروژه های عظیمی در سطح کشور ایران و کشورهای همسایه اجرا کرده است. شما نیز می توانید جهت اطلاع از قیمت و خرید بچینگ پلانت با کارشناسان شرکت در ارتباط باشید.