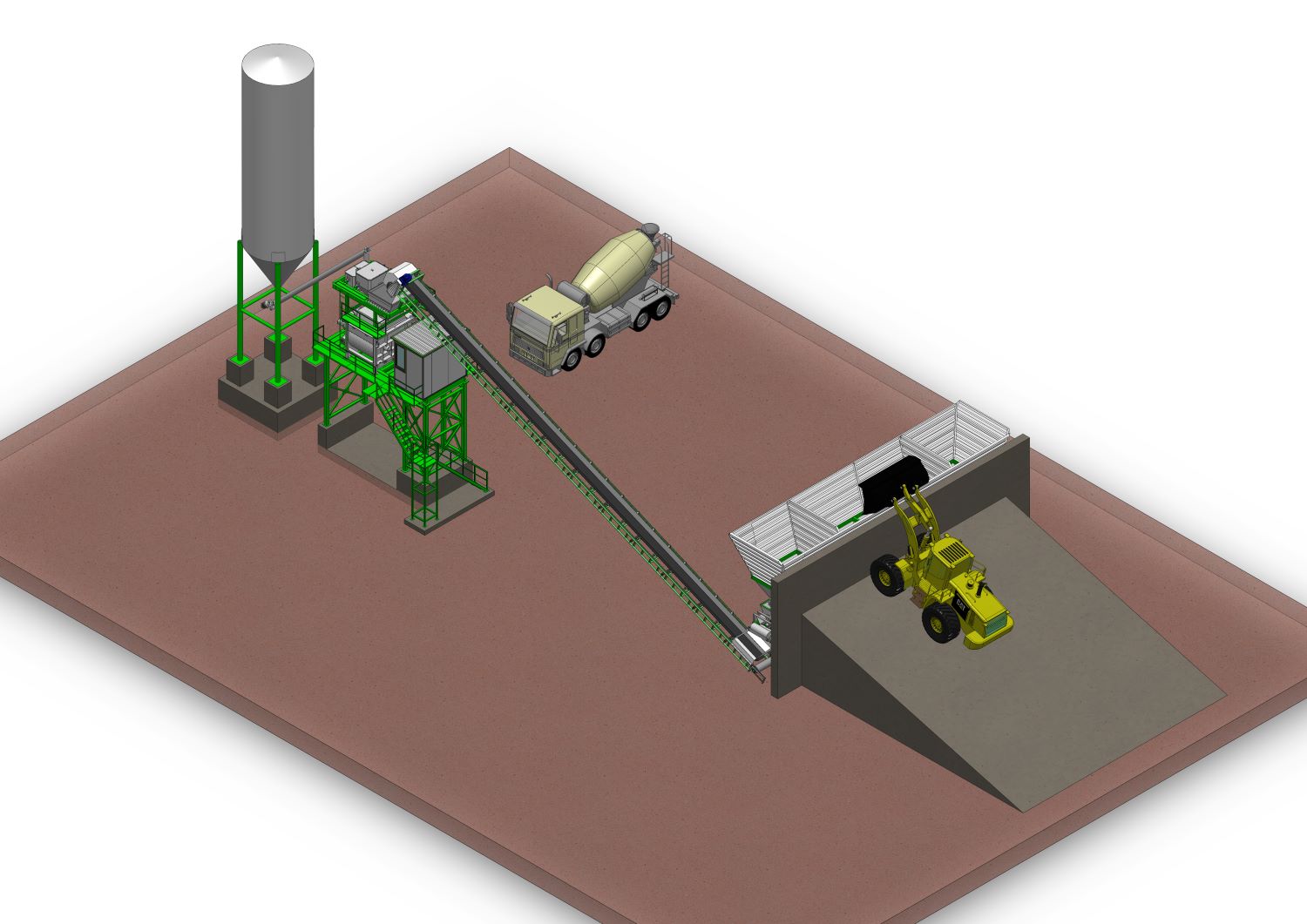

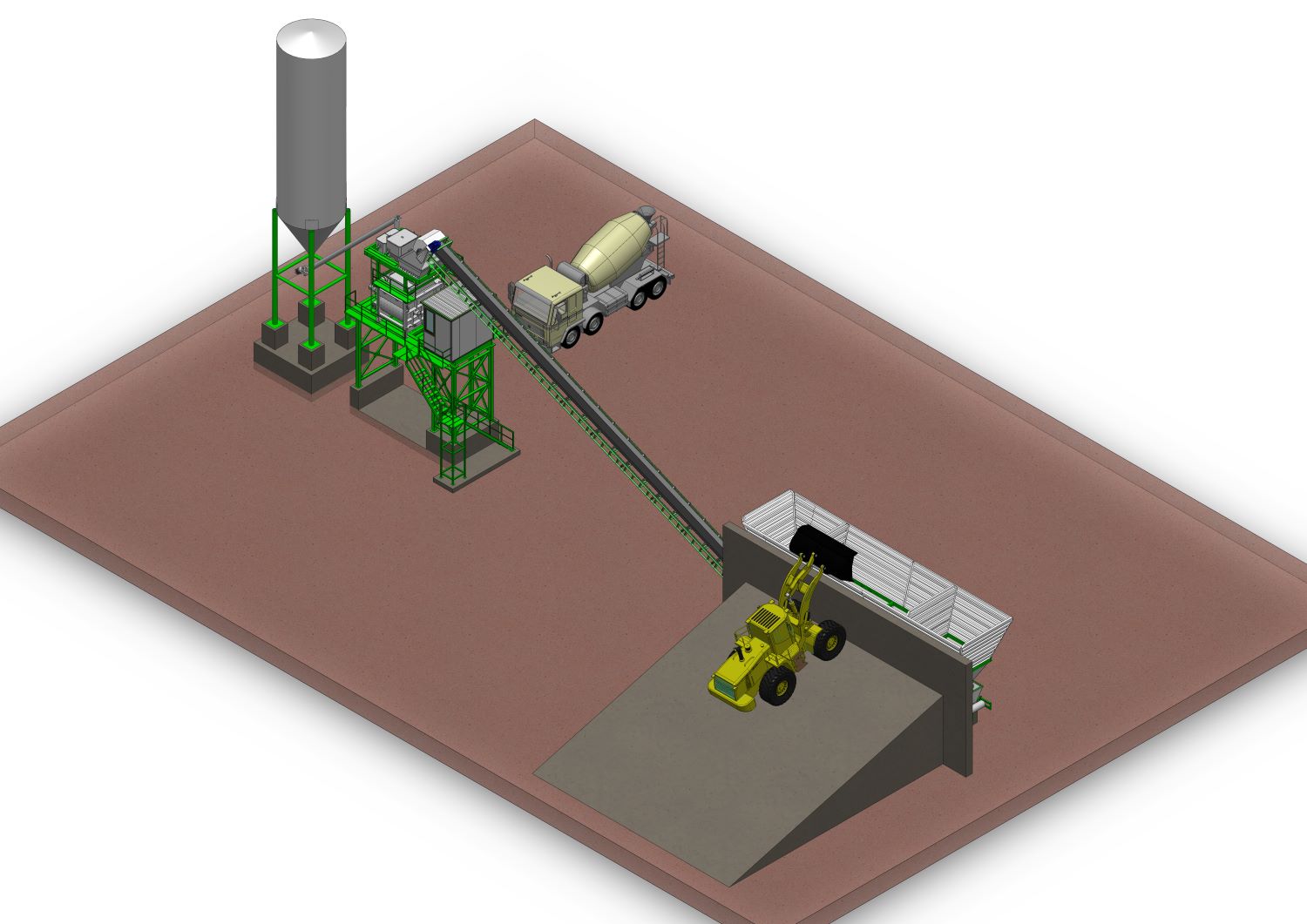

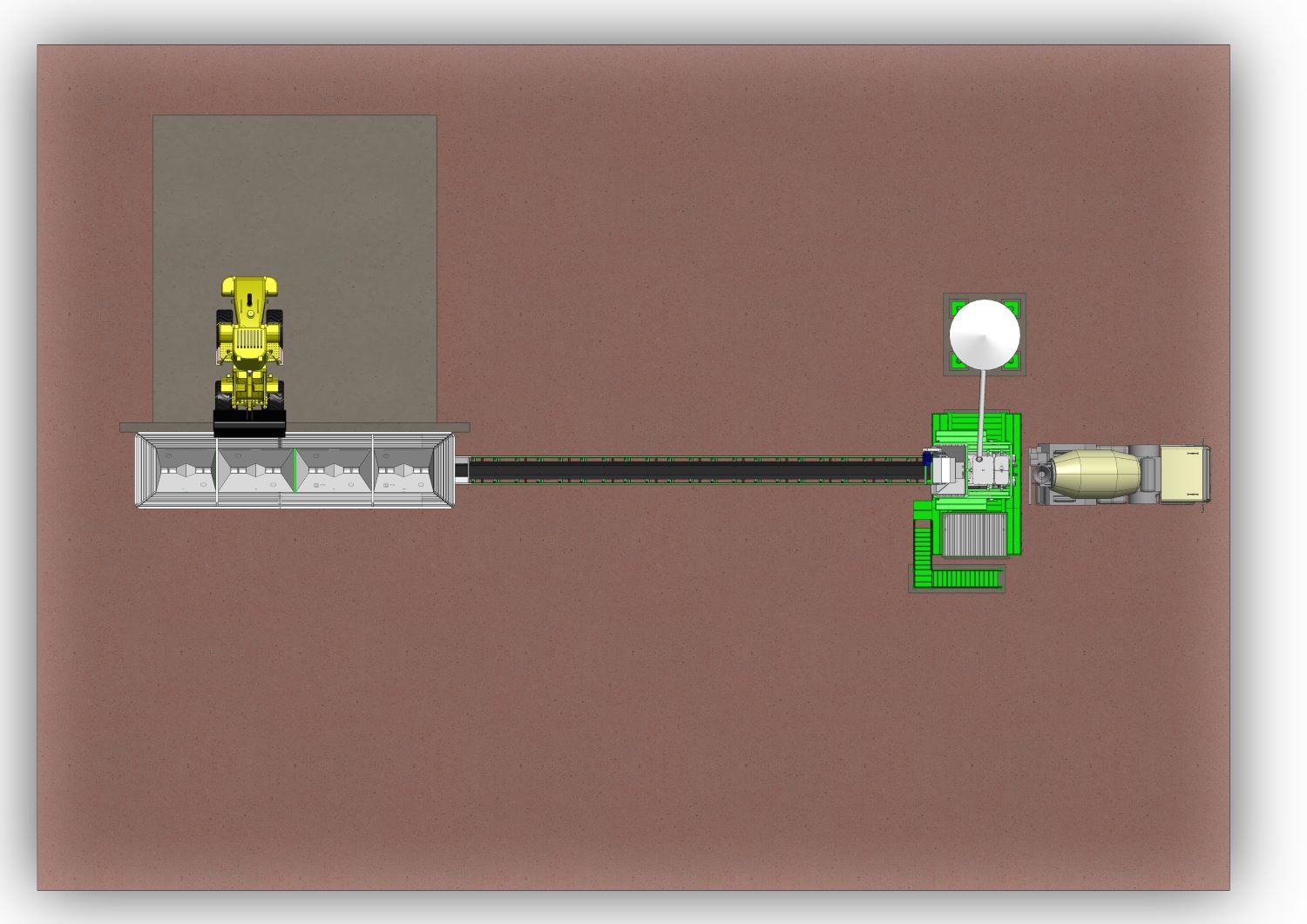

Twin Shaft Concrete Batching Plant – 1 m³

Model: BPT 60

Mixer Output Capacity (per batch): 1 m³

Mixer Power: 2 × 25 hp

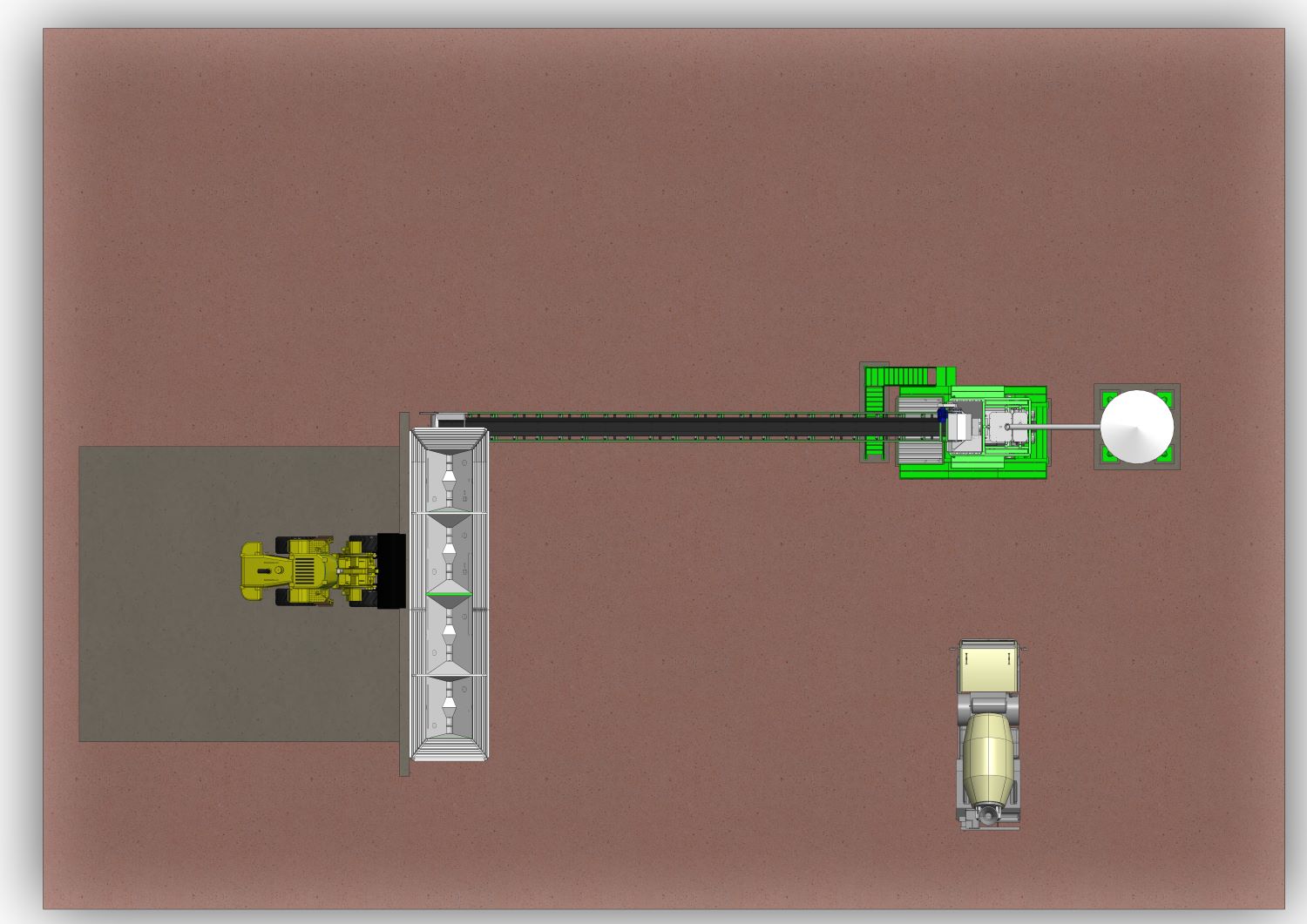

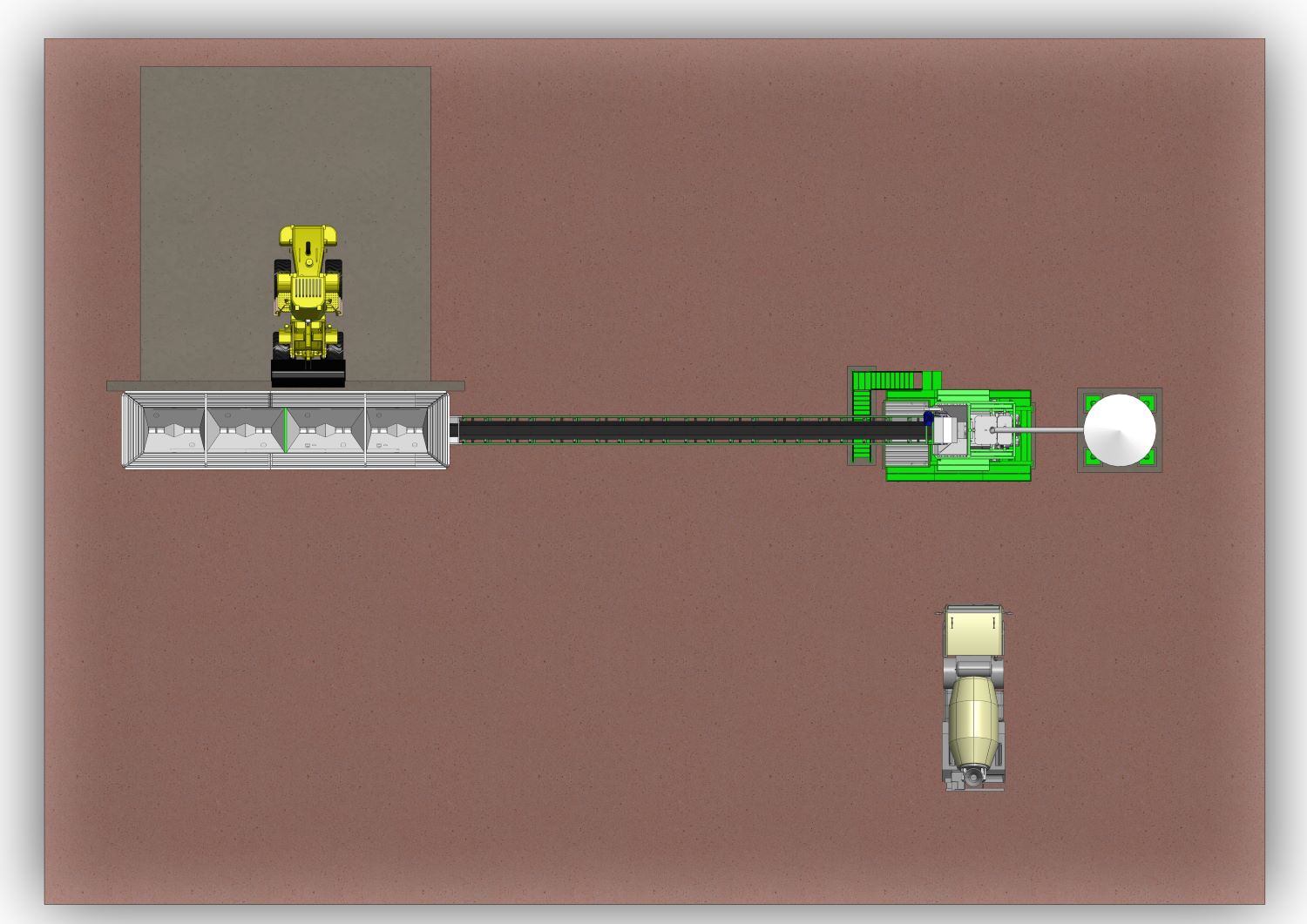

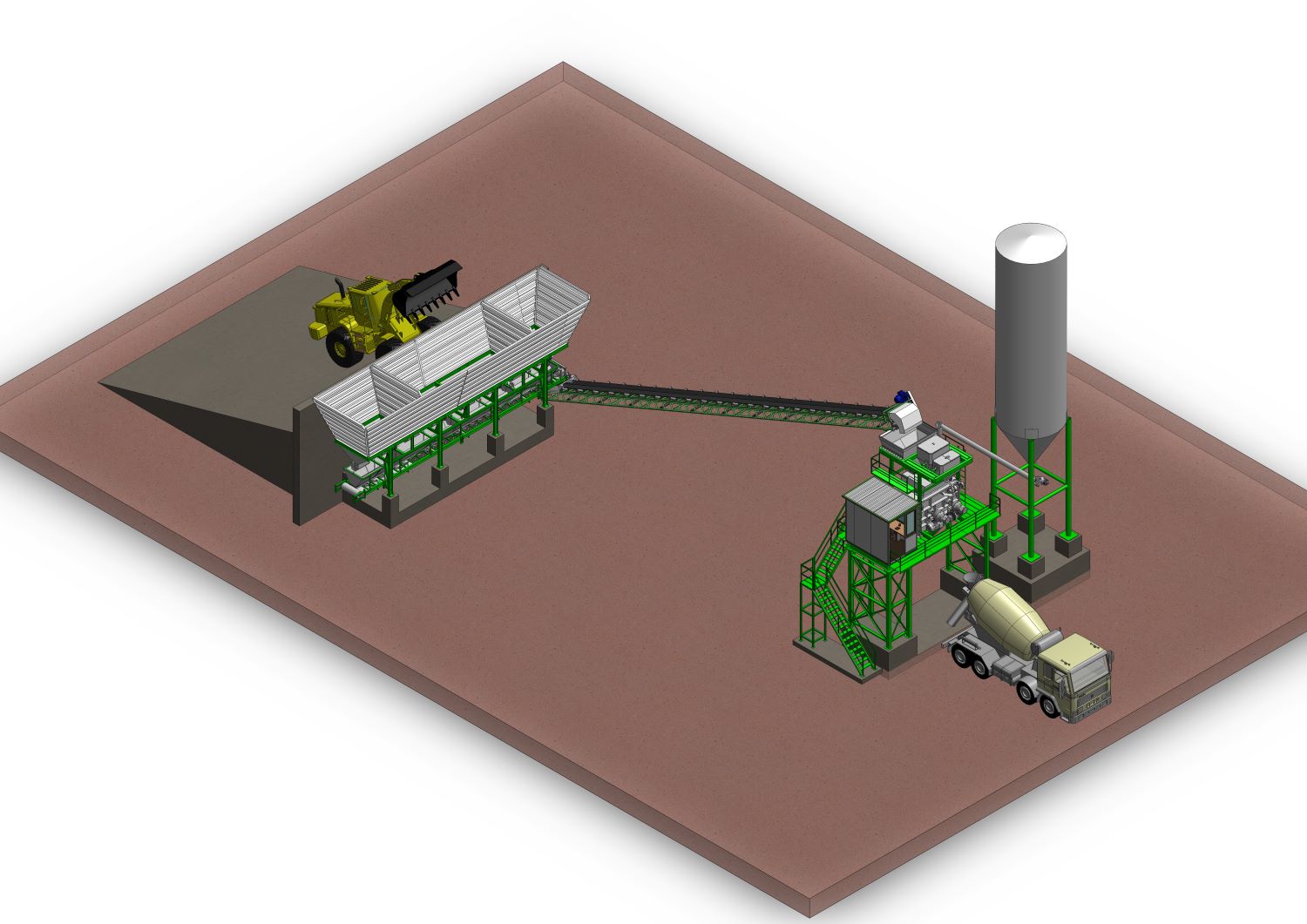

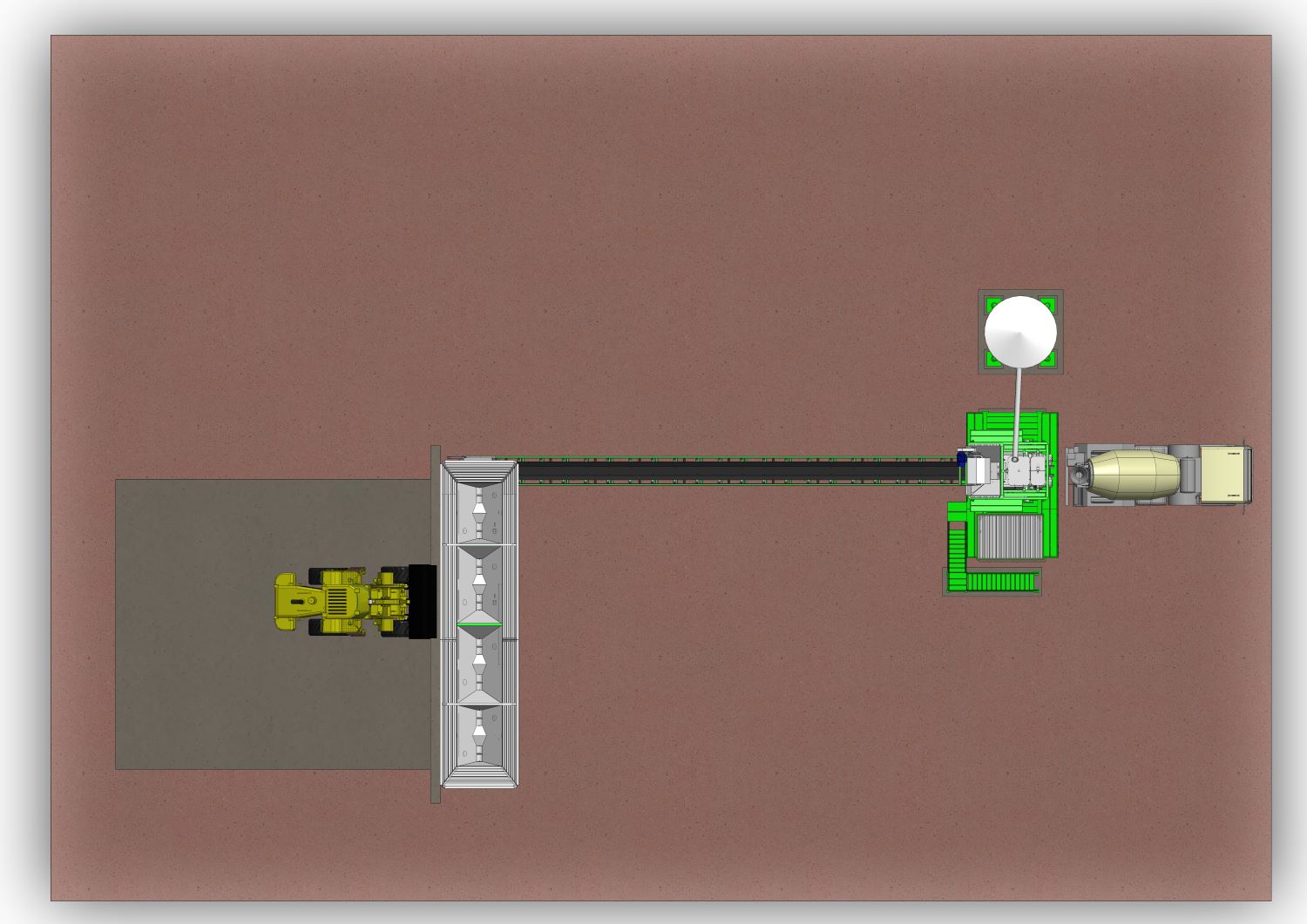

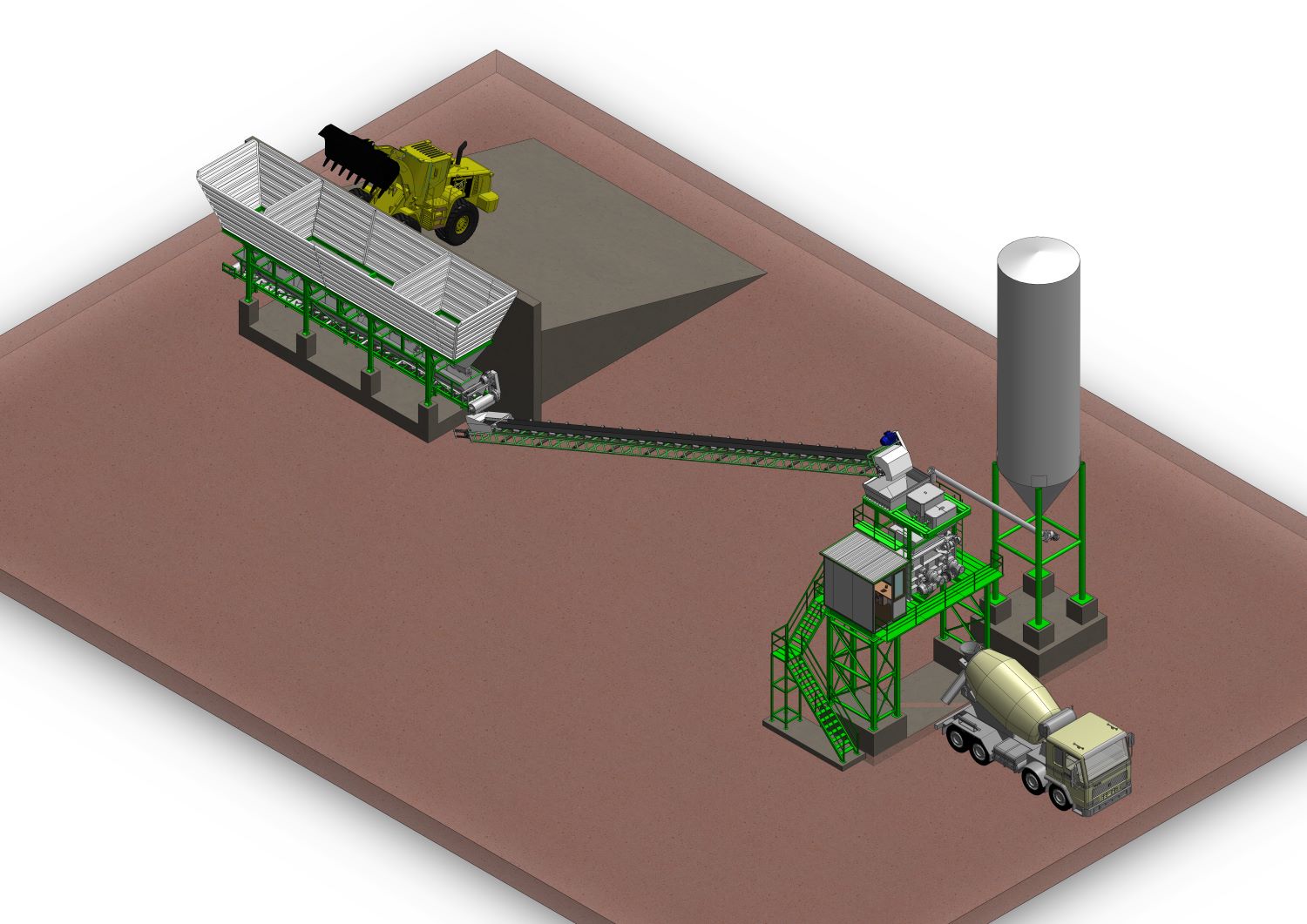

Aggregate Storage Bins: 4 × 15 m³

Aggregate Weighing Belt Width: 600 mm

Aggregate Weighing Belt Length: 12 m

Aggregate Transfer Belt Width: 600 mm

Aggregate Transfer Belt Length: ~ 23 m

Aggregate & Cement Weighing Capacity: 2500 / 500 kg

Cement Screw Diameter: 8 inch

Cement Screw Length: 7 m

Concrete Discharge Height: 4.1 m

Air Compressor: 450 lit/min

Waiting Hopper Capacity: 1400 lit

In projects where concrete is directly transferred from the batching plant to the concrete pump, continuous pouring is not always feasible and occasionally must be paused. To retain the concrete during these pauses, a secondary mixer is used. Its volume is considered to be at least twice the main mixer’s capacity. The waiting hopper overlaps the transfer and mixing times, reducing the cycle time of each batch by up to 25%. A metallic cover over the transfer belt not only enhances the visual appeal but also prevents the rubber belt from heating, thereby avoiding excessive aggregate temperature. It increases belt durability and prevents rainwater from affecting the declared mix design. A walkway with grating floor is installed along the belt for maintenance and inspection purposes. With the increasing demand for specialty concretes, the Twin Shaft Batching Plants by Standard Machine are equipped to handle a wide range of additives in gel, liquid, slurry, and powder forms.

Additionally, it allows loading and mixing of a batch directly from the weighing belt during mixer changeover. In this configuration, as soon as the mixer is positioned under the loading point, the discharge gate opens and concrete is unloaded, achieving more than 25% efficiency improvement compared to a standard system.

Liquid additives are pumped to a tank above the mixer and added after weighing via load cells.

Powder additives are added via screw conveyor and weighing bucket.

Gel and slurry additives can be produced, weighed, and transferred to the mix using colloidal mixers manufactured in-house.